Supply chain – and procurement optimization is a matter for the boss

In February 2020, immediately before the shutdown, ADCONIA conducted a survey among more than 450 entrepreneurs and managing directors to determine the importance of procurement and supply chain for sustainable corporate success. The understanding of how procurement optimization should look like in the organization was very different.

The answers were not surprising. On the one hand, they confirmed that, with regard to sustainability in the consumption of resources, corporate cost efficiency, lean value-added processes and risk management, those responsible for procurement and the supply chain in the company have a decisive role to play. We can only agree with this.

It gets exciting from the moment you add two further aspects – namely:

- organizational anchoring and integration of procurement and supply chain in the corporate hierarchy

- structure and structure of the concrete target matrix in the company – i.e. the active, comprehensible integration of the procurement and supply chain into the medium and long-term corporate objectives

Prioritization and importance – necessity of procurement optimization

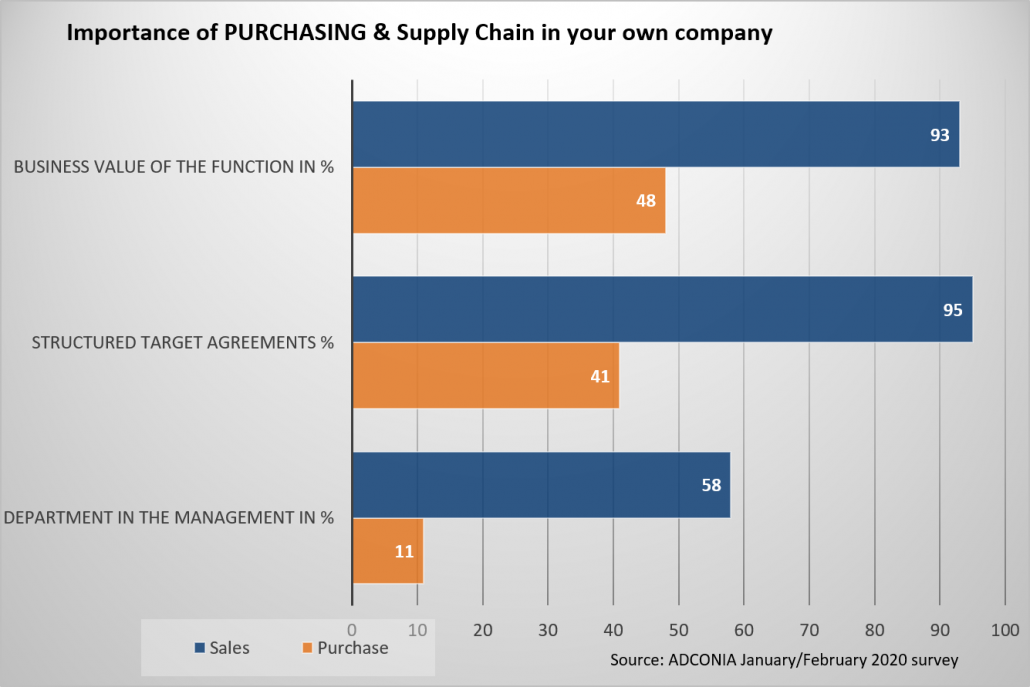

ADCONIA has carried out a comprehensive evaluation of this. The result is sobering. There is a discrepancy between the rational classification of the importance of the procurement and supply chain function for one’s own corporate success and the actual operative implementation of this corporate insight, especially in German medium-sized businesses.

For example, only just under 11% of the companies surveyed can directly identify the functions of supply chain and procurement as management tasks. A further 37% of the companies have placed procurement and supply chain functions in the first hierarchical level below management and are thus actively shaping purchasing and supply chain strategies.

For comparison:

More than 58% of the same companies have the sales function (at least organizationally) directly under the management. In another 35% of the companies, it is directly assigned to the management in terms of expertise and discipline.

Even more sobering is a look at the target agreements for procurement and supply chain in the companies.

In only 41% of the companies surveyed did the procurement or supply chain organisation have a written target agreement. Of these 41%, 68% had a maximum of two targets – mainly savings and delivery reliability. Directly related incentives and variable salary components for the responsible persons were only 7% of the surveyed companies.

For comparison:

100% of all surveyed companies stated that they had a target agreement with the sales department, 95% of them in writing. In 79% of the companies, the sales department had more than 4 targets. In 89%, variable salary components directly linked to the target agreement were agreed with the sales managers.

It cannot be assumed that these widespread corporate structures have changed fundamentally since February 2020.

The period of organizational restructuring in procurement and the supply chain

At the same time, structured procurement optimization and that of the supply chain at the present time offer opportunities and potential that can give the individual company a considerable boost in overcoming economic challenges. The mere realization that this is the case does not help any company. What is necessary is an entrepreneurial prioritization and implementation of the available findings. Active, timely procurement optimization is one of the central responsibilities of every company management.

A procurement and supply chain optimization targets at the first step:

- Cost reduction potentials

- securing and improving results and

- Risk minimization within the supply chains

For this purpose, the „classic“ levers of material group management and supplier management are applied in an updated and contemporary form – enriched with numerous best-practice approaches from diverse projects of the recent and recent past.

In the medium and long term, it serves the purpose of „operational excellence“. By this we understand

- clear responsibilities

- distinct responsibilities

- controlled processes

- joint objectives

This is achieved by continuously synchronizing and optimizing the company’s goals with the processes of the entire value chain. A special focus is placed on procurement and the supply chain as the largest cost factor, often ahead of personnel costs

Supply chain and procurement optimization are therefore much more than the short-term improvement of a quarterly result. They are cornerstones of successful corporate management. The right time to start is always right now.

Gregor van Ackeren

Managing Director